What Is the Difference Between XL4005 and XL4015?

Choosing between XL4005 and XL4015 is not just about current ratings.

It is about control behavior, thermal reality, noise, and long-term reliability.

On paper, they look similar.

In real designs, they behave very differently.

This guide explains how and why—with engineering depth, simple language, and practical advice.

No myths. No marketing shortcuts.

Overview of XL4005 and XL4015 Buck Converters

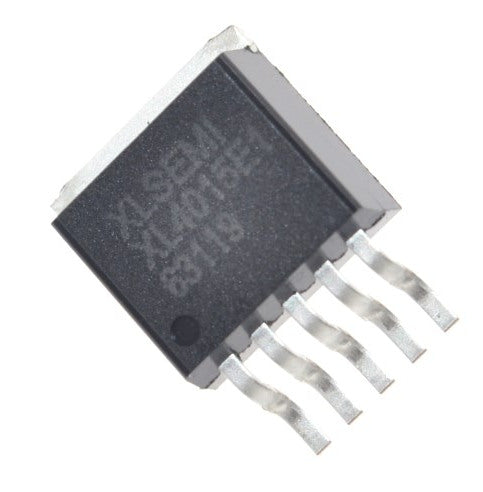

Both XL4005 and XL4015 are step-down (buck) DC-DC converters made by XLSEMI, a Chinese analog IC vendor widely used in consumer, industrial, and DIY power designs.

XLSEMI chips are popular because they are:

- Low cost

- Easy to source

- Simple to design with

However, they are also heavily cloned, which affects performance and trust.

Why XL4005 and XL4015 Are Often Compared

They share:

- Similar pin counts

- Adjustable output voltage

- Availability as cheap DC-DC modules

But they target different load classes.

One is a true mid-power regulator.

The other is a high-current workhorse.

Understanding that distinction avoids burned boards—and burned budgets.

Typical Users and Search Intent

| User Type | What They Care About |

|---|---|

| Engineers | Stability, thermal margin, EMI |

| Buyers | Cost, availability, consistency |

| DIY / Makers | “Does it really handle 5A?” |

Core Electrical Specifications Comparison

This is where the first illusion appears.

Input Voltage and Current Capability

| Parameter | XL4005 | XL4015 |

|---|---|---|

| Max Input Voltage | 32V | 36V |

| Rated Output Current | 5A (peak) | 5A (continuous*) |

| Typical Continuous Current | ~2.5–3A | ~4–5A |

| Switching Frequency | 180 kHz | 180 kHz |

*With proper thermal design.

Key truth:

A “5A” label means nothing without thermal headroom.

Low-cost XL4005 modules rarely sustain more than 3A without overheating.

XL4015 is built to actually survive high current.

Why 5A Claims Are Often Misleading

- Small inductors saturate early

- Thin PCB copper traps heat

- No airflow assumptions

As Jim Williams famously said at Linear Technology:

“The datasheet lies less than the module.”

Control Architecture and Regulation Behavior

This is the real divider.

Voltage-Mode vs. Current-Mode Control

- XL4005: Voltage-mode control

- XL4015: Current-mode control

Why it matters:

| Aspect | Voltage-Mode (XL4005) | Current-Mode (XL4015) |

|---|---|---|

| Load Transient | Slower | Faster |

| Stability | Load-dependent | More robust |

| Compensation | External sensitive | Internally easier |

Current-mode control reacts instantly to load changes.

That makes XL4015 more stable in real systems.

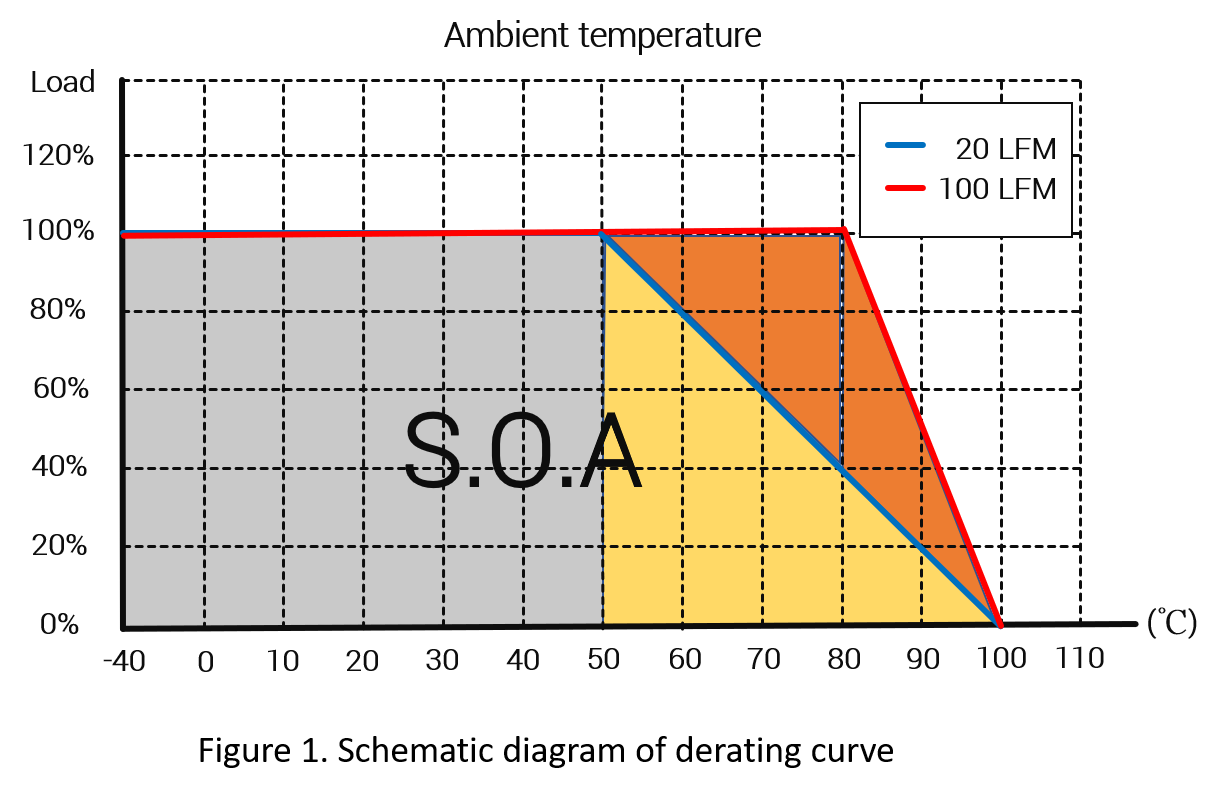

Efficiency and Thermal Performance

Efficiency Across Load

- Light load: similar

- Heavy load: XL4015 wins clearly

At 24V → 5V:

- XL4005 drops efficiency fast above 2.5A

- XL4015 stays stable near 90% (with good layout)

Thermal Reality

XL4005:

- Smaller die

- Higher junction rise

- Needs aggressive derating

XL4015:

- Larger die

- Better heat spreading

- Survives long-term stress

Heat kills silicon.

Slowly. Quietly. Permanently.

Protection and Safety Features

Protection is not optional.

It is survival.

| Feature | XL4005 | XL4015 |

|---|---|---|

| Over-Current | Yes | Yes (better tuned) |

| Short-Circuit | Basic | Hiccup mode |

| Thermal Shutdown | Yes | Yes |

| Soft-Start | Limited | Improved |

| UVLO | Basic | More predictable |

XL4015 handles faults more gracefully, especially during startup into heavy loads.

Noise, Ripple, and Output Quality

Switching noise defines where you can use the chip.

Ripple and EMI Comparison

- XL4005: Higher ripple under load

- XL4015: Cleaner output, lower peak noise

Noise-Sensitive Loads

| Application | Recommended |

|---|---|

| MCU / Logic Rails | XL4015 |

| RF Modules | XL4015 + LC |

| Audio Circuits | XL4015 only |

| Motors / LEDs | Either |

If you hear whining or see ADC jitter—

The converter is speaking.

Package, Modules, and Mechanical Differences

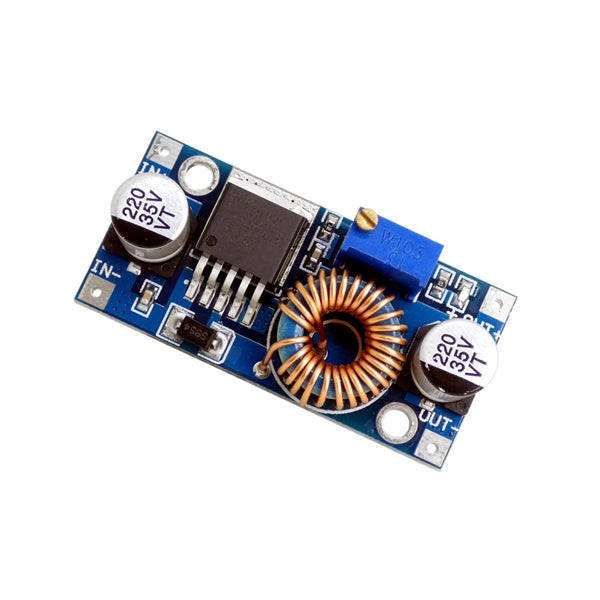

Most users encounter these chips as modules, not bare ICs.

Common Module Formats

| Aspect | XL4005 Modules | XL4015 Modules |

|---|---|---|

| Heatsink Area | Small | Large |

| Inductor Size | Smaller | Larger |

| Board Thickness | Thin | Thicker |

| Reliability | Inconsistent | Better |

XL4015 modules dominate the market for a reason:

They fail less.

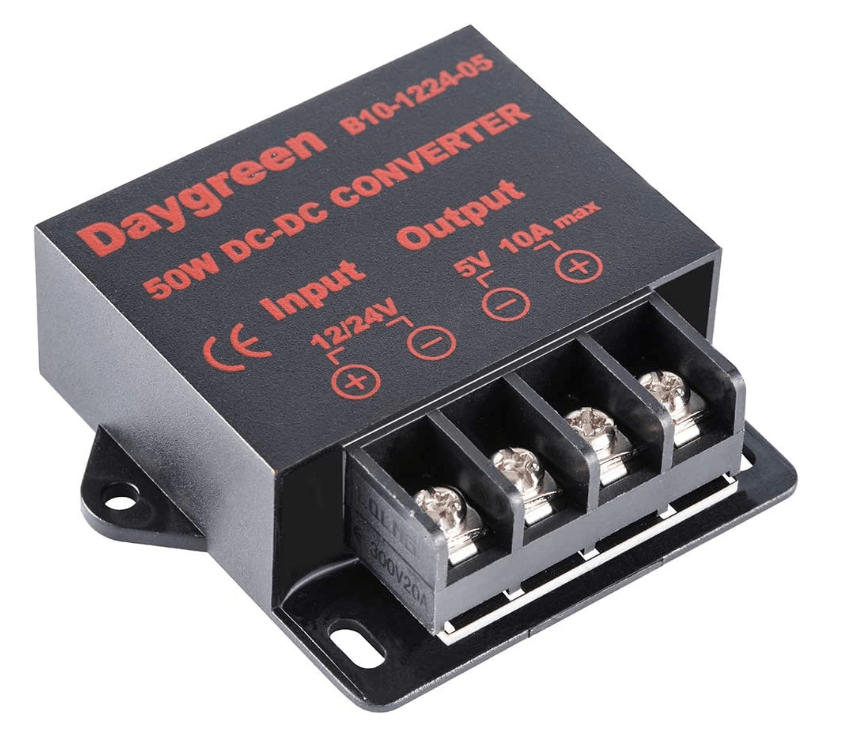

Application Scenarios and Use Cases

When XL4005 Is the Better Choice

- Space-limited designs

- ≤2A continuous current

- Cost-sensitive consumer products

When XL4015 Excels

- 24V → 5V or 12V rails

- Continuous high current

- Industrial or bench supplies

- Automotive auxiliary rails (non-critical)

Decision Guide: Choosing Between XL4005 and XL4015

Quick Design Checklist

| Question | Choose |

|---|---|

| >3A continuous? | XL4015 |

| Noise-sensitive load? | XL4015 |

| Tight PCB space? | XL4005 |

| Long-term reliability? | XL4015 |

| Cheapest BOM only? | XL4005 |

Final Recommendation

- Engineers: XL4015

- Product managers: XL4015

- DIY beginners: XL4015

- Ultra-low-cost designs: XL4005 (with caution)

In power design, margin is money saved later.

Frequently Asked Questions

Is XL4015 better than XL4005?

Yes—for most real-world loads above 2.5A.

Can XL4005 replace XL4015?

Electrically maybe. Thermally and safely—often no.

Which is more efficient?

XL4015 under medium to heavy load.

Which is safer for 24V to 5V?

XL4015, without question.

Final Thought

Power converters don’t fail loudly.

They fail eventually.

Choosing XL4015 is not overkill.

It is foresight.