Understanding LDO vs Buck Converters: A Practical Guide for Engineers, Buyers, and Decision Makers

Power regulation looks simple on paper. Step voltage down. Feed the load. Move on.

In real products, that choice can make or break efficiency, thermal safety, EMI compliance, battery life, and even supply-chain stability. This guide cuts through theory and focuses on practical engineering trade-offs between LDOs (Low Dropout Regulators) and Buck Converters.

Short sentences. Clear logic. Real-world decisions.

1. Introduction to LDO and Buck Converters

Every electronic system lives and dies by its power rails. A noisy rail can kill RF performance. A hot regulator can shorten product life. A poor choice can inflate BOM cost for years.

LDOs and buck converters dominate low-voltage regulation, but they solve problems in very different ways. One favors simplicity and silence. The other favors efficiency and muscle.

This guide is written for:

- Engineers designing reliable power trees

- Buyers balancing cost, availability, and risk

- Decision makers optimizing long-term product value

The goal is not theory.

The goal is better decisions.

2. What Is an LDO (Low Dropout Regulator)?

An LDO is a linear voltage regulator that maintains a stable output as long as the input stays slightly higher than the output.

How It Works (Conceptually)

An LDO behaves like a controlled resistor. It burns excess voltage as heat to keep output steady.

“What you don’t convert, you dissipate.”

This is the core truth of linear regulation.

Key Characteristics of LDOs

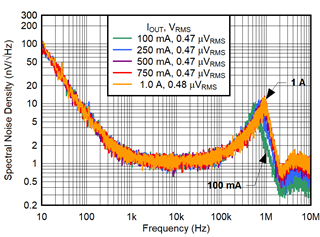

- Very low output noise

- Excellent PSRR (power-supply rejection)

- Minimal external components

- Fast transient response

Typical LDO Applications

- RF circuits

- ADC and DAC reference rails

- Low-current logic supplies

- Post-regulation after a switching converter

Limitations

- Efficiency collapses at large voltage drops

- Heat rises linearly with load current

- Not suitable for high-power rails

Rule of thumb:

If Vin − Vout is large and current is high, an LDO will suffer.

3. What Is a Buck Converter?

A buck converter is a switching regulator that efficiently steps voltage down using inductors, switches, and energy storage.

How Buck Converters Work

Instead of burning voltage, a buck converter chops, stores, and averages energy.

The result:

- Much higher efficiency

- Lower heat

- Wider input voltage range

Key Characteristics

- 90–95% efficiency is common

- Supports high output current

- Handles wide Vin ranges

- Requires careful layout and filtering

Typical Buck Converter Applications

- 12V to 5V or 3.3V rails

- Battery-powered systems

- Automotive electronics

- High-current digital rails

Limitations

- Generates switching noise

- EMI compliance requires effort

- More components, more design time

A buck converter rewards discipline. It punishes shortcuts.

4. Key Electrical Parameters Engineers Must Compare

Choosing blindly is expensive. Compare intelligently.

Critical Parameters Side-by-Side

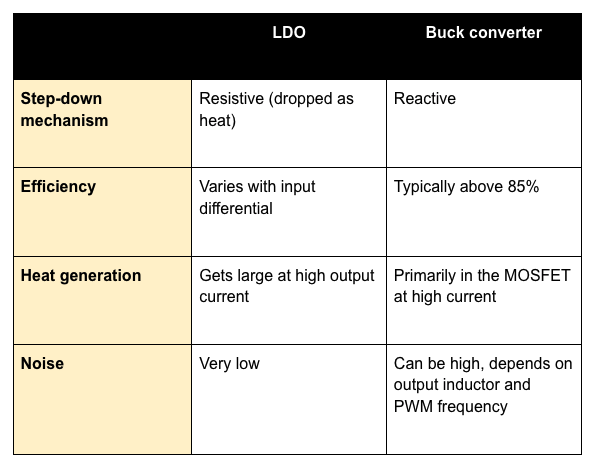

| Parameter | LDO | Buck Converter |

|---|---|---|

| Efficiency | Low at large Vin–Vout | High across wide range |

| Output Noise | Very low | Higher (ripple present) |

| PSRR | Excellent | Moderate |

| Quiescent Current | Ultra-low possible | Higher (varies by mode) |

| External Parts | Minimal | Inductor, caps, sometimes diode |

| EMI Risk | Very low | Medium to high |

What Matters Most?

- Low noise? LDO wins

- High current? Buck wins

- Battery life? Depends on load profile

- Thermal margin? Buck usually safer

No parameter lives alone. Always consider the system.

5. Impact of Input–Output Voltage Differences

Voltage delta is destiny.

High Vin to Low Vout

Example: 12V → 3.3V at 500mA

- LDO efficiency ≈ 27%

- Buck efficiency ≈ 90%

Heat will not be polite. It will be destructive.

Small Voltage Differential

Example: 3.6V → 3.3V

- LDO efficiency ≈ 92%

- Simplicity wins

Wide Input Ranges

Automotive (9–36V) and adapters demand bucks.

LDOs simply cannot survive the dissipation.

Proverb from power design veterans:

“Linear regulators scale poorly. Switching regulators scale beautifully.”

6. Thermal Design and Packaging Constraints

Power lost becomes heat. Heat becomes failure.

Power Dissipation Formula (LDO)

[

P = (V_{IN} – V_{OUT}) \times I_{OUT}

]

No shortcuts. No mercy.

Thermal Reality

| Aspect | LDO | Buck |

|---|---|---|

| Heat Source | Pass element | Switching losses |

| PCB Copper Needed | High at power | Moderate |

| Package Sensitivity | Very high | Moderate |

| Derating Needed | Aggressive | Less severe |

Practical Insight

An LDO that looks fine electrically can fail thermally in a sealed enclosure.

Always check θJA, ambient temperature, and airflow.

7. EMI, Compliance, and Noise Considerations

EMI Reality Check

- LDOs are quiet by nature

- Bucks must be managed

EMI Sources in Buck Converters

- Fast switch edges

- Inductor current ripple

- Poor ground return paths

Best Practices

- Tight current loops

- Solid ground planes

- LC filters when needed

- Spread-spectrum switching

Common Strategy

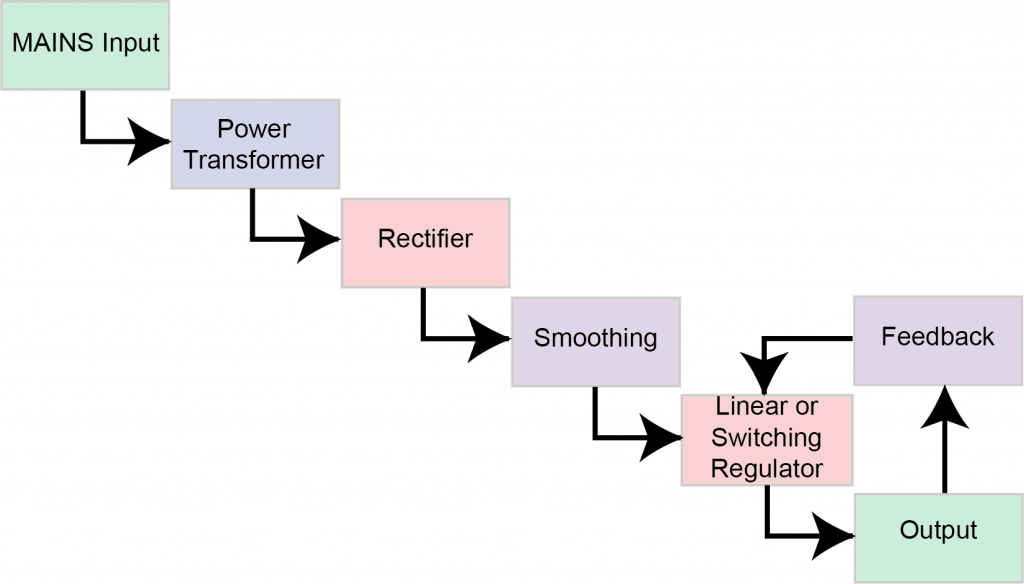

Buck + LDO cascade

Buck handles efficiency.

LDO cleans the noise.

This hybrid approach dominates professional designs.

8. Cost, Reliability, and Final Selection Guidance

BOM vs Total Cost

A buck costs more upfront.

But heat sinks, failures, and recalls cost far more.

Reliability Perspective

| Factor | LDO | Buck |

|---|---|---|

| Parts Count | Low | Higher |

| Stress Level | High at power | Lower |

| Long-Term Reliability | Load-dependent | Generally strong |

When to Choose an LDO

- Low current

- Small voltage drop

- Noise-sensitive rails

- Simple designs

When to Choose a Buck Converter

- High current

- Large Vin–Vout difference

- Battery or automotive systems

- Thermal constraints

Best-Practice Architecture

Buck for bulk power. LDO for precision rails.

This is not a compromise.

It is maturity.

Final Takeaways

- LDOs trade efficiency for silence and simplicity

- Buck converters trade complexity for efficiency and power

- Voltage difference drives thermal reality

- EMI is manageable with good design

- Hybrid architectures often win

Design power like it matters—because it always does.

If you’d like, I can also provide:

- A one-page selection checklist

- A decision flowchart

- Application-specific recommendations (automotive, IoT, medical, industrial)

Just tell me.