Power Supply Rejection Ratio (PSRR) Explained: Why It Matters for IC Design and Purchasing

Power Supply Rejection Ratio—PSRR—sounds abstract. It is not.

It is one of the clearest predictors of whether a circuit will behave calmly or chaotically when power is imperfect.

And power is always imperfect.

Executives feel PSRR as customer complaints.

Engineers fight it in the lab.

Buyers see it as cost, risk, and supplier credibility.

As the old engineering proverb goes:

“A clean signal starts with a dirty supply handled well.”

This article explains PSRR in depth—but in clear language—so design teams and purchasing teams can make better, cheaper, safer decisions.

What Is Power Supply Rejection Ratio (PSRR)?

PSRR describes how well an IC blocks power supply noise from reaching its output.

In simple terms:

- A high PSRR IC ignores supply noise

- A low PSRR IC passes that noise straight into your signal

Definition in Simple Terms

PSRR is the ratio between:

- unwanted voltage changes on the power supply

- and the resulting voltage error at the output

The higher the ratio, the better the rejection.

How PSRR Is Expressed (dB)

PSRR is measured in decibels (dB):

| PSRR (dB) | Noise Rejection Meaning |

|---|---|

| 20 dB | Weak rejection |

| 40 dB | Moderate rejection |

| 60 dB | Strong rejection |

| 80–100 dB | Excellent (low-frequency only) |

Every 20 dB means 10× better rejection.

What PSRR Reveals

PSRR tells you:

- How clean your output really is

- How sensitive the IC is to regulator ripple

- Whether PCB fixes will save you—or not

Why PSRR Matters Across the Organization

PSRR is not just an engineering number. It is a business risk indicator.

Executives & Founders

Poor PSRR causes:

- Field failures

- Audio hiss

- Display flicker

- Sensor drift

These become returns, brand damage, and lost trust.

Engineers & R&D

Low PSRR means:

- Hard-to-debug noise

- Late-stage redesigns

- Endless “why does this only fail on Friday?” moments

Product Managers

PSRR affects:

- Spec compliance

- Feature trade-offs

- Whether performance degrades in real use

Procurement

PSRR drives:

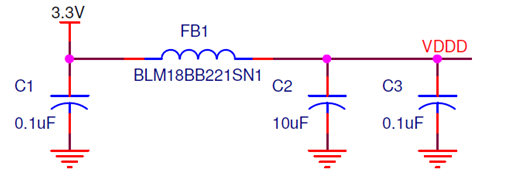

- Hidden BOM cost (filters, ferrites, LDOs)

- Supplier risk

- Over-optimistic datasheets

How PSRR Is Defined: The Technical Perspective

The PSRR Formula

PSRR is defined as:

[

PSRR = 20 \log \left(\frac{\Delta V_{supply}}{\Delta V_{output}}\right)

]

This means:

- Small output change = good

- Large output change = bad

High vs. Low PSRR

- High PSRR → robust against noise

- Low PSRR → output tracks supply fluctuations

Typical vs. Minimum Specs

Datasheets love typical PSRR.

Designs fail at minimum PSRR.

| Spec Type | Risk Level |

|---|---|

| Typical | Marketing-friendly |

| Minimum | Design-relevant |

| Over temperature | Reality |

PSRR vs. Related Power Integrity Metrics

PSRR is often confused with other specs. They are not the same.

| Metric | What It Measures |

|---|---|

| PSRR | Supply noise → output |

| CMRR | Common-mode signal rejection |

| Line Regulation | DC supply changes |

| Ripple Rejection | AC ripple at fixed freq |

Common Misconception

High line regulation ≠ high PSRR

They operate in different frequency domains.

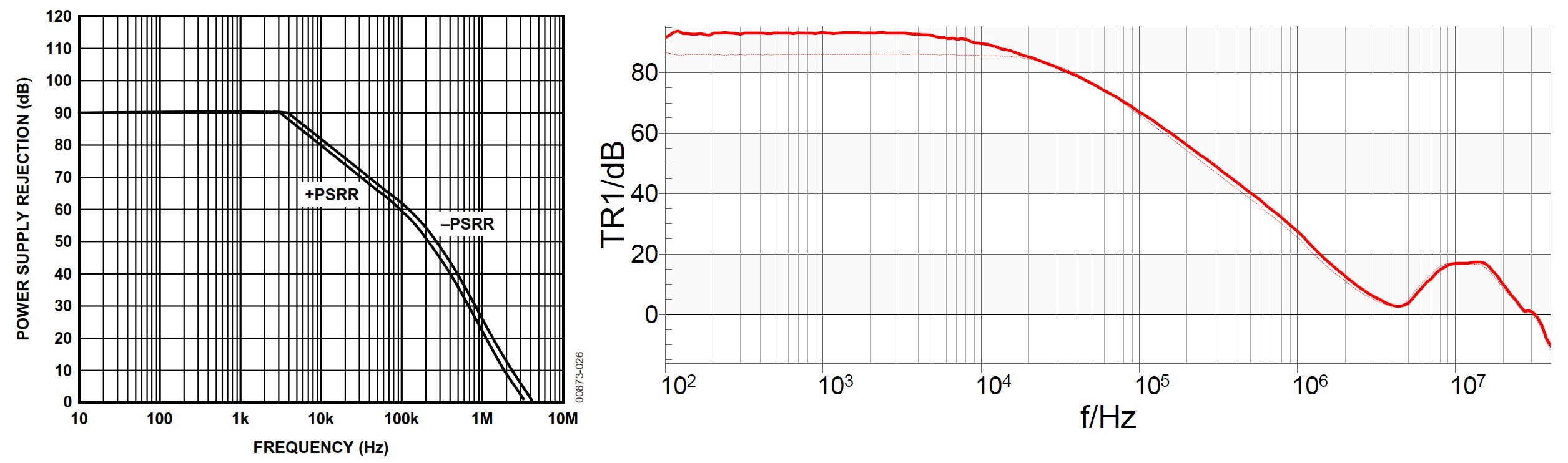

PSRR vs. Frequency: Why a Single Number Is Misleading

PSRR Is Frequency-Dependent

PSRR is strong at low frequencies.

It collapses at high frequencies.

A device with:

- 90 dB at 10 Hz

- may have only 20 dB at 1 MHz

Why PSRR Degrades

- Parasitic capacitances

- Finite gain bandwidth

- Internal transistor coupling

Why Curves Matter

The curve tells the truth.

The headline number sells the part.

Load, Temperature, and Process Effects on PSRR

Load Dependence

PSRR changes with current:

| Load Condition | PSRR Behavior |

|---|---|

| No-load | Looks great |

| Light-load | Often worst |

| Heavy-load | Internal gain drops |

Temperature Effects

As temperature rises:

- Gain falls

- Bias shifts

- PSRR drops

Process Corners

Worst-case silicon can lose 20–30 dB of PSRR.

This is why:

“Typical specs build demos. Worst-case specs ship products.”

PSRR in Common Integrated Circuits

Operational Amplifiers

Poor PSRR causes:

- Offset drift

- Gain error

- Noise floor rise

LDO Regulators

PSRR determines:

- How much switching noise leaks through

- Whether downstream analog survives

ADCs and DACs

Supply noise directly reduces:

- SNR

- ENOB

- Measurement accuracy

Mixed-Signal SoCs

Shared supplies = shared pain.

Digital noise always wins without isolation.

PCB Layout and Measurement Reality

Layout Can Destroy PSRR

Even the best IC fails with:

- Long supply traces

- Shared return paths

- Missing high-frequency caps

Decoupling Matters

Good PSRR assumes:

- Tight loop areas

- Multiple capacitor values

- Low inductance paths

Why Lab PSRR Looks Worse

Datasheets assume:

- Ideal supplies

- Perfect grounding

- Zero EMI

Real boards never do.

How to Improve PSRR in Design and Purchasing

Design Techniques

- Use local LDOs near sensitive blocks

- Split analog and digital supplies

- Short, wide power traces

- Proper capacitor placement

How Buyers Should Evaluate PSRR

Ask suppliers:

- Is this typical or guaranteed?

- At what frequency?

- At what load and temperature?

- Where is the curve?

System-Level Trade-Off

Higher PSRR ICs often:

- Reduce filters

- Simplify layout

- Cut debug time

Higher IC cost can mean lower system cost.

Key Takeaways

- PSRR measures how well ICs reject dirty power

- A single PSRR number is misleading

- Frequency, load, temperature, and layout matter

- Typical specs are optimistic; minimum specs are real

- Good PSRR reduces cost, risk, and redesigns

In the end, PSRR is not just an electrical parameter.

It is a confidence metric.

Designs with strong PSRR survive reality.

Designs without it survive only simulations.