Package Marking Codes: Reading IC Labels

Integrated circuits are small.

But the information printed on them is huge.

A few letters, numbers, and symbols can reveal where a chip was made, when it was built, how it must be handled, and whether it can be trusted. In today’s volatile electronics supply chain, reading IC package marking codes is no longer optional. It is a survival skill.

As the old engineering proverb says:

“Trust, but verify.” — widely cited in quality and manufacturing disciplines

This guide explains how to read IC labels, why they matter, and how professionals use them to reduce risk, prevent counterfeits, and protect production lines—all at a 7th-grade reading level, without oversimplifying the truth.

What Are Package Marking Codes?

Package marking codes are identifiers printed directly on an IC package. They communicate critical information in a compact form because space is limited.

Short. Dense. Purpose-built.

What IC Markings Tell You

At a minimum, IC markings can reveal:

- Who made the chip

- What the part number is (full or abbreviated)

- When it was manufactured

- Which lot or batch it came from

- How it should be handled and stored

Why They Matter in Modern Supply Chains

Global sourcing has changed everything. Parts now move through:

- Multiple distributors

- Long storage cycles

- Secondary and spot markets

Without accurate markings, traceability collapses.

“If you cannot trace it, you cannot trust it.” — common principle in ISO-based quality systems

Who Must Read IC Labels

This information is not just for engineers.

- Buyers verify authenticity

- QA teams confirm compliance

- Manufacturing avoids assembly errors

- Management reduces recall and audit risk

Core Information Found on IC Package Markings

Every IC package is a puzzle. These are the most common pieces.

Manufacturer Identification

Usually a logo or short code.

It confirms the original manufacturer—not the distributor.

Part Number (Full or Abbreviated)

Due to space limits, many chips use:

- Truncated part numbers

- Family codes

- Internal product identifiers

Always cross-check with the datasheet.

Date Codes

Date codes show when the chip was produced, not shipped.

Common formats include:

| Format | Meaning | Example |

|---|---|---|

| YYWW | Year + week | 2345 = Week 45, 2023 |

| YWW | Year + week | 345 = Week 45, 2023 |

| Vendor-specific | Internal logic | Requires decoding |

Date codes matter for aging, warranty, and FIFO control.

IC Package Type and Orientation Markings

A correct part installed the wrong way is still a failure.

Common IC Package Types

You will often see:

- QFN

- BGA

- SOIC

- TSSOP

- DIP

Each package has unique marking constraints.

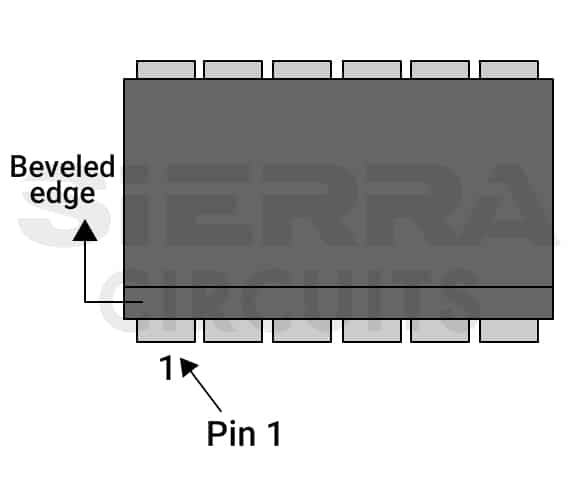

Pin 1 Indicators

Orientation markings include:

- Dots

- Notches

- Chamfered corners

Misreading Pin 1 can destroy boards instantly.

Top-Side vs Bottom-Side Markings

BGA packages are especially tricky.

Some data appears:

- On the top mold

- On the substrate bottom

- Or not at all

Never assume. Always verify.

Lot, Batch, and Traceability Codes

This is where markings become mission critical.

What Lot Codes Represent

Lot or batch codes link chips to:

- A specific wafer

- A production run

- A test flow

Why Lot Codes Matter

They support:

- Failure analysis

- Yield tracking

- Field returns

- Targeted recalls

In automotive, medical, and aerospace electronics, traceability is mandatory, not optional.

Country of Origin Codes

Some ICs include country identifiers. Others do not.

Important distinctions:

- Wafer fabrication location

- Assembly location

- Test location

These may all differ.

| Stage | Possible Country |

|---|---|

| Wafer Fab | Taiwan |

| Assembly | Malaysia |

| Test | Philippines |

Country data affects compliance, tariffs, and geopolitical risk.

Moisture Sensitivity and Handling Codes

Plastic ICs absorb moisture.

That moisture can explode during reflow.

Moisture Sensitivity Level (MSL)

MSL indicates how long a part can stay out of dry storage.

| MSL | Floor Life |

|---|---|

| MSL 1 | Unlimited |

| MSL 3 | 168 hours |

| MSL 5 | 48 hours |

IC Markings vs External Labels

MSL is often printed on:

- Reels

- Trays

- Moisture barrier bags

Rarely on the IC itself.

Ignoring this data causes latent failures.

Environmental and Material Compliance Markings

Regulations are strict. And getting stricter.

RoHS and Pb-Free

Common indicators include:

- “Pb-Free”

- “e3”

- Green dot symbols

These confirm lead-free termination.

Other Environmental Codes

Some vendors add:

- REACH indicators

- Halogen-free markings

- Internal green compliance codes

These are essential for regulated markets.

Marking Technologies and Counterfeit Risk

How a marking is applied matters as much as what it says.

Laser-Etched vs Ink-Printed

Laser markings:

- Are permanent

- Resist solvents

- Age better

Ink markings:

- Can fade

- Can smear

- Are easier to alter

Counterfeit Detection

Red flags include:

- Uneven fonts

- Inconsistent depth

- Sanded surfaces

- Over-marking

“Counterfeit parts do not fail immediately. They fail when it hurts most.” — widely cited in aerospace QA training

Best Practices for Reading and Verifying IC Markings

No single marking tells the whole story.

Cross-Verification

Always compare:

- IC markings

- Datasheets

- PCNs

- External packaging labels

Lot Consistency

Parts from the same reel should:

- Share date codes

- Match font styles

- Look identical

Know the Limits

IC packages do not show everything:

- Full compliance status

- Electrical screening level

- Internal process changes

When in doubt, manufacturer confirmation is required.

Why Package Marking Codes Matter for Risk Management

Package markings are not trivia.

They are risk controls.

They protect against:

- Counterfeit parts

- Wrong revisions

- Compliance violations

- Costly recalls

Strong marking verification supports:

- ISO audits

- JEDEC alignment

- Customer trust

In the end, accurate IC identification is about confidence.

Confidence in sourcing.

Confidence in assembly.

Confidence in the final product.

Final Thought

IC package marking codes may look small.

But they carry the weight of quality, safety, and reputation.

Read them carefully.

Verify them always.

Because in electronics, the smallest details decide the biggest outcomes.