What Is Load Regulation and Line Regulation?

Introduction: Why Load and Line Regulation Matter in Power Design

Stable voltage is the quiet backbone of every electronic system. When it holds, everything works. When it drifts, problems appear—sometimes subtly, sometimes catastrophically.

Load regulation and line regulation describe how well a power supply maintains its output voltage under real-world changes. These two specifications appear in almost every regulator datasheet, design review, and supplier comparison. Yet they are often misunderstood or oversimplified.

Engineers rely on them to protect sensitive circuits.

QA teams use them to predict failures.

Component buyers use them to avoid costly redesigns.

As the saying often attributed to Peter Drucker goes: “What gets measured gets managed.” In power design, load and line regulation are two of the most important measurements you can manage.

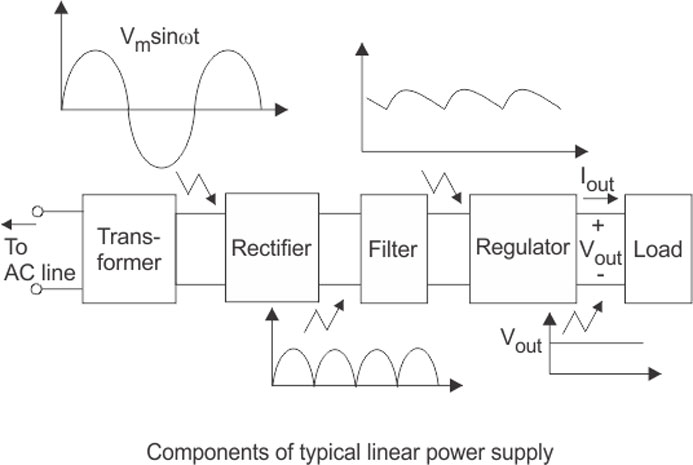

Understanding Load Regulation

Load regulation explains how the output voltage changes when the load current changes, while the input voltage stays constant.

Definition and Basic Concept

In simple terms, load regulation answers one question:

If my circuit suddenly draws more or less current, will the voltage stay the same?

- What changes: Load current

- What remains constant: Input voltage

An ideal power supply would deliver the exact same voltage whether the load is light or heavy. Real supplies never achieve perfection, but good ones come close.

Load Regulation Formula and Calculation

Load regulation is usually expressed as a percentage:

[

\text{Load Regulation (%)} = \frac{V_{no\ load} – V_{full\ load}}{V_{nominal}} \times 100

]

Some datasheets also express it as mV/A, which directly shows how much voltage drops per ampere of load increase.

Step-by-step idea:

- Measure output voltage at light or no load

- Measure output voltage at full rated load

- Compare the difference

Real-World Example

Imagine a 5 V regulator:

- No-load voltage: 5.05 V

- Full-load voltage: 4.95 V

That 100 mV drop may seem small. But in precision ADCs or RF circuits, it can be the difference between accuracy and noise.

Why Load Regulation Matters

Poor load regulation leads to:

- Logic thresholds drifting

- ADC reference errors

- RF frequency instability

- Reduced reliability under peak load

Voltage-sensitive circuits demand consistency. Load regulation delivers it—or fails to.

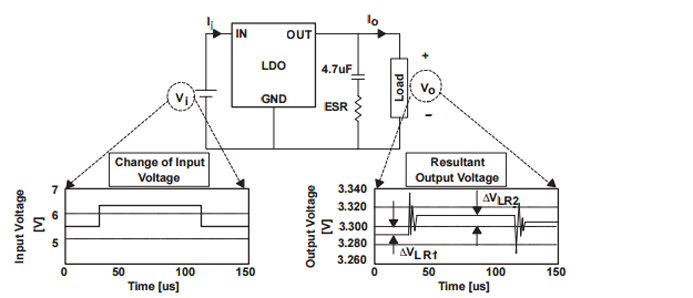

Understanding Line Regulation

Line regulation measures how output voltage changes when the input voltage changes, while the load remains constant.

Definition and Basic Concept

Line regulation answers a different question:

If my input voltage rises or falls, will the output remain stable?

- What changes: Input voltage

- What remains constant: Load current

This is critical when power sources are unstable, noisy, or shared.

Line Regulation Formula Explained

Line regulation is typically calculated as:

[

\text{Line Regulation (%)} = \frac{V_{out\ max} – V_{out\ min}}{V_{out\ nominal}} \times 100

]

It may also be specified as mV/V, showing how much output shifts per volt of input change.

Practical Example

A regulator rated for 9 V–15 V input:

- Output changes from 5.01 V to 4.99 V

- That 20 mV swing reflects its line regulation performance

Why Line Regulation Is Critical

Line regulation protects systems from:

- Brownouts and surges

- Battery discharge variation

- Automotive cold-crank events

Without it, upstream instability flows straight into downstream damage.

Key Differences Between Load Regulation and Line Regulation

Though related, these specs solve different problems.

What Changes vs What Stays Constant

| Specification | What Changes | What Stays Constant |

|---|---|---|

| Load Regulation | Load current | Input voltage |

| Line Regulation | Input voltage | Load current |

Impact on System Stability

- Load regulation dominates in dynamic, current-hungry systems

- Line regulation dominates when the power source is unstable

Typical Applications

| Application Type | More Critical Spec |

|---|---|

| Microcontrollers | Load regulation |

| Battery-powered devices | Line regulation |

| RF & precision analog | Both |

Load and Line Regulation vs Related Specifications

Understanding regulation alone is not enough. Context matters.

Load Regulation vs Load Transient Response

- Load regulation: Static behavior

- Load transient response: Dynamic behavior

A supply may regulate well under steady loads but fail during fast current steps (e.g., 10% → 90%).

Load Regulation vs Output Impedance

Mathematically, poor load regulation often indicates high output impedance. Lower impedance equals tighter voltage control.

Line Regulation vs PSRR

- Line regulation: DC voltage changes

- PSRR: Frequency-dependent noise rejection

Low noise circuits care deeply about PSRR—even when line regulation looks good on paper.

Factors That Affect Regulation Performance

Several internal and external elements shape regulation quality:

- Reference accuracy: Sets the voltage baseline

- Feedback loop design: Determines correction speed

- Pass element resistance: Impacts voltage drop

- Temperature variation: Alters component behavior

- PCB layout: Parasitics quietly degrade performance

As the proverb often attributed to William Thomson (Lord Kelvin) reminds us:

“If you cannot measure it, you cannot improve it.” Regulation exposes these weaknesses.

Typical Specifications and Industry Benchmarks

Typical Load Regulation Values

| Regulator Type | Typical Load Regulation |

|---|---|

| Linear regulator | 0.1% – 0.5% |

| LDO | 0.05% – 0.3% |

| Switching regulator | 0.5% – 2% |

Typical Line Regulation Test Conditions

| Condition | Notes |

|---|---|

| Input sweep | Min to max rated input |

| Load | Held constant |

| Temperature | Often 25°C only |

Always read the fine print. “Typical” is not “guaranteed.”

How to Use Load and Line Regulation in Real Decisions

Why Regulation Alone Is Not Enough

Great regulation cannot fix:

- High ripple and noise

- Poor transient response

- Thermal runaway

- Low efficiency

A balanced design wins.

Prioritizing the Right Spec

- Portable devices: Line regulation first

- Industrial systems: Line + thermal behavior

- Precision analog/RF: Tight load regulation and PSRR

Using Specs for Better Sourcing

Avoid common mistakes:

- Comparing specs measured under different conditions

- Ignoring temperature drift

- Assuming tighter regulation always means better system performance

Strong suppliers specify worst-case, not just best-case numbers.

Conclusion: Designing and Buying with Confidence

Load regulation and line regulation are not marketing fluff. They are predictors of real-world behavior.

- Load regulation tells you how a system handles demand

- Line regulation tells you how it handles instability

Used together—and interpreted carefully—they help engineers design robust systems, buyers choose reliable components, and teams avoid painful redesigns.

Measure wisely. Compare carefully. Design with confidence.

If you’d like, I can next:

- Convert this into a featured-snippet comparison table

- Optimize it for commercial buyer intent

- Adapt it for automotive, industrial, or consumer electronics audiences